Revolutionizing Industries: The Pinnacle of Aluminum Alloy Die Casting in China

Introduction: Aluminum alloy die casting has emerged as a game-changer in the manufacturing landscape, particularly in China. This cutting-edge process involves the injection of molten aluminum alloy into precision-designed molds, yielding complex and high-quality components. As industries worldwide seek lightweight yet robust solutions, China has positioned itself as a frontrunner in aluminum alloy die casting, contributing significantly to sectors such as automotive, electronics, and consumer goods.

Overview of Aluminum Alloy Die Casting in China: With a rich historical background in manufacturing, China has seamlessly integrated aluminum alloy die casting into its industrial fabric. The country’s prowess in this field is underscored by current market trends, showcasing a robust growth trajectory. The demand for aluminum alloy die-cast components has surged, driven by the relentless pursuit of efficiency, cost-effectiveness, and design flexibility.

Advantages of Aluminum Alloy Die Casting: The intrinsic benefits of aluminum alloy die casting make it a preferred choice in manufacturing processes. The lightweight properties of aluminum, coupled with a high strength-to-weight ratio, redefine the possibilities in various applications. Notably, the cost efficiency and unparalleled design flexibility further elevate the appeal of this method in diverse industries.

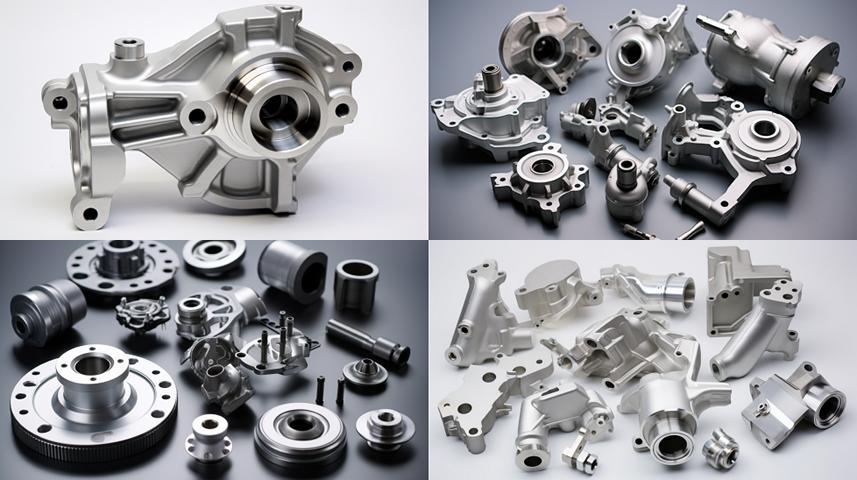

Key Applications in China: China’s aluminum alloy die casting prowess is prominently visible in key sectors. In the automotive industry, components ranging from engine parts to transmission housings benefit from the lightweight and durable nature of die-cast aluminum. Similarly, the electronics industry leverages die-cast enclosures and heat sinks, while consumer goods, including household appliances and sporting equipment, embrace the versatility of aluminum alloy die casting.

Manufacturing Process: A cornerstone of China’s success in aluminum alloy die casting lies in the meticulous manufacturing process. From the intricate design and production of molds to the precise stages of melting, injection, cooling, and ejection, each step is a testament to the commitment to quality and precision. Finishing touches further enhance the end product’s aesthetics and functionality.

Quality Control and Standards: In aligning with global quality standards, China’s aluminum alloy die casting industry adheres to stringent inspection and testing protocols. Certification and compliance with industry standards ensure that the produced components meet the highest quality benchmarks. This commitment to quality bolsters the reputation of Chinese manufacturers in the global market.

Challenges and Opportunities: While the industry thrives, challenges such as environmental concerns and increased competition necessitate continuous innovation. Technological advancements, coupled with the identification of emerging applications, present opportunities for growth and differentiation. As China navigates these challenges, the aluminum alloy die casting sector is poised for sustained success.

Leading Companies in China: Prominent companies in China’s aluminum alloy die casting sector play a pivotal role in shaping the industry’s landscape. Through innovative practices and a commitment to excellence, these companies contribute significantly to the market share, driving the industry forward and expanding its global footprint.

Future Outlook and Trends: The future of aluminum alloy die casting in China is marked by ongoing technological innovations, market expansion, and a growing global presence. The industry’s commitment to sustainability further underscores its forward-thinking approach. As new applications emerge and consumer expectations evolve, China’s aluminum alloy die casting industry is well-positioned for a dynamic and prosperous future.

Conclusion: In conclusion, China’s aluminum alloy die casting industry stands at the forefront of global manufacturing, with its commitment to innovation, quality, and sustainability. As industries continue to evolve, the versatility and efficiency offered by aluminum alloy die casting ensure its enduring relevance. China’s journey in revolutionizing industries through this advanced manufacturing process serves as a beacon for the future of manufacturing worldwide.

Are you in need of high-quality aluminum die casting services? Look no further than CNM Tech China die casting manufacturer! Our team of experts specializes in aluminum, zinc, and magnesium die casting, as well as machining parts, metal stamping, and plastic molds making.

With over 18 years of experience, you can trust that our die casting products are exemplary and cost-effective. We employ advanced equipment and machinery to ensure the highest quality solutions.

We have been made many type of aluminum die casting, zinc die casting, magnesium die casting from flow meter housing and valves to lighting fixture parts, automobile parts, and decorative hardware, we manufacture a wide range of products to meet your needs. And, as an added bonus, we also export various aluminum casting, zinc die casting, and magnesium casting products, as well as machining parts and injection molded parts.

Don’t settle for subpar aluminum casting services. Choose CNM Tech die casting China manufacturer for exceptional quality and affordable prices. Contact us today to learn more about our services and how we can help meet your die casting needs!